|

Reasons

for using ABBFIX

Resin Anchor Grout

-

Fast

setting polyester resin with rapid strength gain allows loads

to be applied within 2 hours.

-

Easy

to mix and place.

-

Fixing

cannot be vibrated out.

-

Cheaper

than mechanical fixings and resin cartridges.

-

Uses

quality polyester resin which has over 30 years proven performance

in the construction industry.

-

Manufactured

under BSI Quality Assurance Scheme BS 5750: Part 2, ISO 9002,

EN 29002.

-

ABBFIX

Resin Anchor Grout is moisture tolerant in rotary percussive

holes.

Application

Anchoring with ABBFIX Resin Anchor Grout is primarily dependent

on mechanical interlock and not adhesive bond.

The following points should therefore be observed:

1)

Create a rough sided dry hole preferably by rotary percussive

drilling. If Diamond drilled holes have been made these must be

under-reamed or roughened and all dust removed.

2) Use fixings such as deformed bolts or bars which have been

degreased and are completely free of rust.

3) Drill holes which are not more than 12 mm greater in diameter

than the diameter of the bolt or bar. If excess dimensions are

encountered seek advice from ABBOT Fixings representatives.

4) Cleanliness is the most important factor, do not expect

to anchor rusty fixings into dirty damp holes.

When using ABBFIX Anchor Grout simply pour the mixed grout

into the hole and insert, with a twisting action, the bolt or

bar into the base.

To avoid excess displacement of grout and therefore wastage

estimate the quantity per hole in advance.

(Please

consult the Abbot Sales Office for further details).

Technical

service and representation

We can provide technical service through our Technical Department

or alternatively, please contact one of our Sales Staff at the

Office.

Shelf

Life of ABBFIX

Initial set times are dependent on ambient temperature relative

to either Summer or Winter grade resin being used.

The exothermic reaction of the grout components is also influenced

by the bulk of material mixed at any one time.

To avoid wastage do not mix more material than can realistically

be used within the following setting times.

|

Ambient

Temp

|

Winter

Grade

approximate

setting time

|

Summer

Grade

approximate

setting time

|

|

0

deg C

5 deg C

|

40-45

mins

25-30 mins

|

Do

not use

below 7 deg C

|

|

7

deg C

|

22-27

mins

|

65-75

mins

|

|

10

deg C

|

17-22

mins

|

50-57

mins

|

|

15

deg C

|

12-16

mins

|

32-37

mins

|

|

20

deg C

25 deg C

|

Do

not use

above 17 deg C

|

20-24

mins

15-16 mins

|

For ambient temperatures above 25 deg C a Tropical Grade is available.

|

|

Typical

properties

All

tests carried out at 20 deg C

|

Compressive

strength

BS6319 pt 2

|

1

hour

4 hours

24 hours

|

80

N/mm2

95 N/mm2

110 N/mm2

|

|

Tensile

strength

BS6319 pt 7

|

24

hours

|

12

N/mm2

|

|

Flexural

strength

BS6319 pt 3

|

24

hours

|

28

N/mm2

|

|

Bond

strength to concrete

|

failure

in the concrete

|

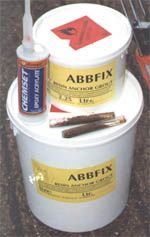

Packaging

ABBFIX Resin Anchor Grout is available in the following pack

sizes : 2.5 litres and 10 litres.

Storage

Shelf life is in excess of 6 months when stored in cool dry

conditions.

Mixing

Small packs contain a plastic pail for use as a mixing vessel.

The

contents of small size packs can either be mixed mechanically

or by hand using a flat blade, stirring all the filler/hardener

powder into the complete volume of resin from the can until a

smooth, even consistency is attained.

When mixing mechanically use a slow speed stirrer or an electric

drill with a stirring attachment producing 200-400 rpm.

The large packs have the facility for proportioning the contents

using cups provided.

The ratio for mixing is:

1 volume of resin:

2 volumes of filler/hardener powder.

These units can be mixed mechanically, or if only small quantities

are required mix by hand using a flat blade.

Health

and safety/COSHH regulations

In its liquid state ABBFIX Resin Anchor Grout is flammable

with a flash point of 30 deg C. The material is easily and safely

handled provided working instructions are properly followed and

site cleanliness is observed.

Operatives are advised to avoid direct contact by using barrier

creams and protective clothing. In the event of contamination

the product should be removed with soap and water or proprietary

cleansing creams. Working areas should be well ventilated. For

further details on safe handling, please refer to the ABBOT Fixings

Safe Handling Guide, which also contains all data and information

relating to the Control of Substances Hazardous to Health (COSHH)

regulations.

Strength development

The ultimate strength of the fixing is determined by:

With

good installation after a 2-hour curing period at 20 deg C the

compressive strength of the grout will be in excess of 40 N/mm2

at which point the anchorage will fully sustain its design load.

Any failure under test after this time will generally occur

in either the bar or substrate.

Important

Note

To the best of our knowledge and belief, the information contained

in this leaflet is true and accurate, but as conditions of use

and any labour involved are beyond our control, the end user must

satisfy himself by prior testing that the product is suitable

for his specific application, and no responsibility can be accepted,

or any warranty given by our Representatives, Agents or Distributors.

|

![]()

![]()

![]()

![]()